- DIGITAL TWIN

- FACTORY I/O AUTOMATION PROGRAMMING AND SIMULATION

- FACTORY AND WAREHOUSE AUTOMATION SIMULATION SOFTWARE

- WORKSPACE LT ADVANCED ROBOT PROGRAMMING

- M-ROBOT SIMULATION SOFTWARE

- ARISTOSIM ROBOT OFFLINE PROGRAMMING AND SIMULATION

- CNC-MACHSIM VIRTUAL OPERATOR TRAINING

- CNCTRAIN PROGRAMMING AND SIMULATION

DIGITAL TWIN

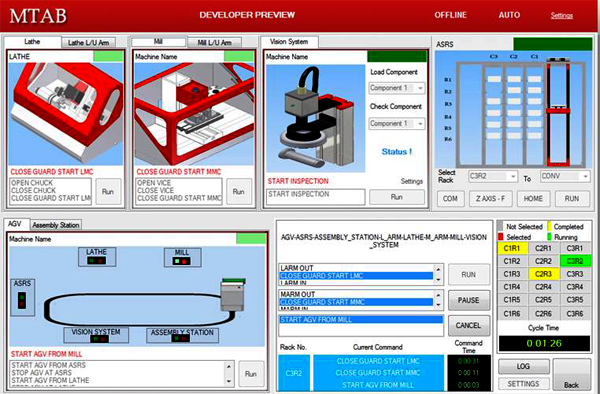

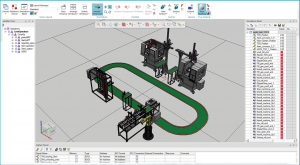

The digital twin is a digital representation of the Smart Factory Automation System presented by MTAB. This optional software comes with the digital model of the factory layout and allows the users and trainees to fully explore a digital factory, working, faults, maintenance and what-if scenario planning in a sophisticated software environment.

The digital twin is a digital representation of the Smart Factory Automation System presented by MTAB. This optional software comes with the digital model of the factory layout and allows the users and trainees to fully explore a digital factory, working, faults, maintenance and what-if scenario planning in a sophisticated software environment. Using software packages, the users can simulate individual machines, combine systems, run plant simulations and run process simulations. It is also possible to control the entire Smart Factory through the digital software, thus allowing the trainees fully experience the working of the industrial shopfloor. The trainees can simulate multiple layouts and study process flow, cycle time optimization, product flow, etc.

Using software packages, the users can simulate individual machines, combine systems, run plant simulations and run process simulations. It is also possible to control the entire Smart Factory through the digital software, thus allowing the trainees fully experience the working of the industrial shopfloor. The trainees can simulate multiple layouts and study process flow, cycle time optimization, product flow, etc.Digital Twin Simulation

Digital twin is a virtual-physical connection which helps you to analyze how a product will perform under various conditions and make adjustments in the virtual world to ensure that the next physical product will perform exactly as planned in the field. With the help of powerful software, you achieve synchronization between product engineering, manufacturing engineering, production, and service operations to maximize your production efficiency. The main features of digital twin is useful in incorporating Multiphysics simulation, data analytics, and machine learning capabilities, digital twins are able to demonstrate the impact of design changes, usage scenarios, environmental conditions, and other endless variables – eliminating the need for physical prototypes, reducing development time and improving quality of the finalized product or process. In this video, now the digital twin demonstration the MTAB smart factory setup consists of ASRS, AGV, FLEXMILL, FLEXTURN, Transfer conveyor, Gantry loading and unloading, Vision Inspection, Assembly station with Robot etc.

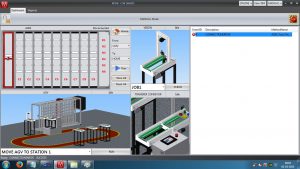

Factory I/O is a didactic tool for individuals performing professional PLC training and education, presenting simulations of industrial plants that can be controlled in realtime. The goal is to make each industrial plant work correctly by using an external PLC. Students will be able to see a PLC in its typical industrial environment and fully understand and program common control tasks.

Factory I/O is a didactic tool for individuals performing professional PLC training and education, presenting simulations of industrial plants that can be controlled in realtime. The goal is to make each industrial plant work correctly by using an external PLC. Students will be able to see a PLC in its typical industrial environment and fully understand and program common control tasks. Each simulation is a complete emulation of a real industrial plant including virtual sensors and actuators. The sensors and actuators data is exchanged between the PLC and the system by a data acquisition board (DAQ) with 32 I/O isolated channels and USB interface.

Each simulation is a complete emulation of a real industrial plant including virtual sensors and actuators. The sensors and actuators data is exchanged between the PLC and the system by a data acquisition board (DAQ) with 32 I/O isolated channels and USB interface. SIMULATION OF INDUSTRIAL PLANTS

SIMULATION OF INDUSTRIAL PLANTSFactory I/O offers five simulations inspired by common industrial plants: Sorting, Batching, Palletizer, Pick & Place and Automatic Warehouse. Each simulation is a typical industrial application of programmable logic controllers (PLC) that will give users the opportunity to practice real world control tasks. Within the simulations, it is possible to interact with all dynamic objects in the simulation and experience the realistic behaviors of gravity, friction, collisions and 3D sound.

The five systems have the following points in common:

- Entry and exit zones, where movable objects (like pallets, cases or parts) are automatically inserted and removed from the scene.

- Limited number of movable objects simultaneously in the system.

- Maximum of 16 sensors (PLC inputs) and 10 actuators (PLC outputs).

- Ability to simulate failures at multiple points to teach troubleshooting.

FACTORY AND WAREHOUSE AUTOMATION SIMULATION SOFTWARE

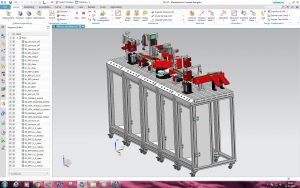

CIMSIM Software is an interactive, easy to use simulation tool for teaching and training in the area of manufacturing automation. CIMSIM has a library of hardware that the users can use in order to build and simulate their own factory floor. The users can customize factory layout, sequence processes, monitor each individual device and process time, simulate process times, learn about how to optimize processes to minimize idle time.

CIMSIM Software is an interactive, easy to use simulation tool for teaching and training in the area of manufacturing automation. CIMSIM has a library of hardware that the users can use in order to build and simulate their own factory floor. The users can customize factory layout, sequence processes, monitor each individual device and process time, simulate process times, learn about how to optimize processes to minimize idle time. It is a great introduction to the multiple technologies that go into a factory, for users to explore in a virtual environment. The Warehouse Automation Simulation training is available for virtually training in the use of logistics and supply chain technologies such as Automatic Storage & Retrieval System, Automatic Guided Vehicle; Transfer Conveyors; Vision Inspection; etc.

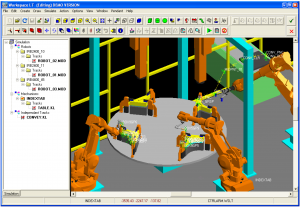

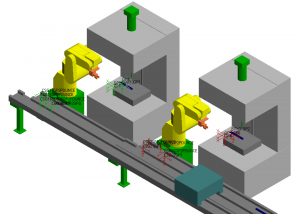

It is a great introduction to the multiple technologies that go into a factory, for users to explore in a virtual environment. The Warehouse Automation Simulation training is available for virtually training in the use of logistics and supply chain technologies such as Automatic Storage & Retrieval System, Automatic Guided Vehicle; Transfer Conveyors; Vision Inspection; etc. WORKSPACE LT brings Industrial Grade Robot and Automation Simulation to Educational Institutions. An industrial solution tuned for education, Workspace LT provides an affordable solution for teaching the concepts and programming of Robots and other manufacturing automation equipment. While targeted at the educational market, it offers full offline programming, and the ability to simulate complex work cells with multiple robots and automation devices. Workspace LT allows you to make maximum use of limited Robot lab resources.

WORKSPACE LT brings Industrial Grade Robot and Automation Simulation to Educational Institutions. An industrial solution tuned for education, Workspace LT provides an affordable solution for teaching the concepts and programming of Robots and other manufacturing automation equipment. While targeted at the educational market, it offers full offline programming, and the ability to simulate complex work cells with multiple robots and automation devices. Workspace LT allows you to make maximum use of limited Robot lab resources. Supports native robot languages, currently supported languages:

Supports native robot languages, currently supported languages:ABB – Arla, Rapid; Adept – VPlus ; Esched – ACL; Fanuc – Karel, TP; JIRA – Strolic; Kawasaki – AS; Mitsubishi – MMB; Motoman – Inform1, Inform2; Nachi – Slim; Unimation – Val1, Val2

What Workspace LT can do:

- Quickly model work cell layouts and evaluate their performance

- Communicate your design concept using state-of-the- art 3D graphics

- Test reach and detect collisions

- Generate Robot programs off-line using a mouse driven menu syste

- Optimize programming using high-level WORKSPACE functions

- Download programs to a robot controller

- 3D CAD Creation, Manipulation and modification capabilities

- Eliminates the need for additional CAD Software for the creation of Geometry

- Workspace LT can import data from other robot and mechanisms or can create additional robots on request

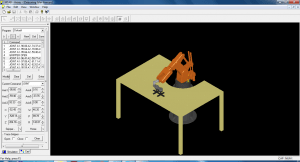

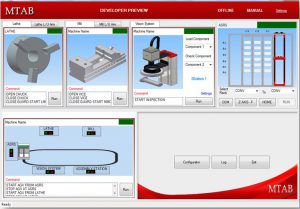

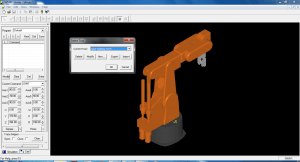

M-Robot is introductory 3D software for robot programming and simulation. This software allows trainees to learn robot teach techniques in a safe environment. Ready-made applications are available to train the user in the operations of the robot such as movement, programming and code generation. You can also create new objects and import into the software. M-Robot has graphics which enable you to visualize the robot from various angles as the robot moves in the simulation window.

Key Features: Easy to use; Axis and Cartesian programming; Onscreen teach pendant; Teach command programming.

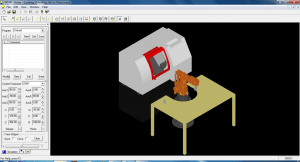

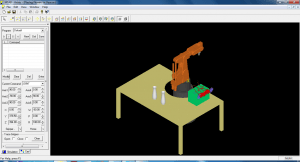

ARISTO SIM is a user-friendly software for robot programming and simulation. Ready-made applications are available to train the user in the operations of the robot such as movement, programming and code generation. This software gives you the flexibility to design your applications and import them into the software for simulation. ARISTOSIM has graphics which enable you to visualize the robot from various angles as the robot moves in the simulated application.

ARISTO SIM is a user-friendly software for robot programming and simulation. Ready-made applications are available to train the user in the operations of the robot such as movement, programming and code generation. This software gives you the flexibility to design your applications and import them into the software for simulation. ARISTOSIM has graphics which enable you to visualize the robot from various angles as the robot moves in the simulated application. The user can simulation movements such as linear, circular, spline path generation and Joint and Cartesian movements. ARISTOSIM includes features such as ability to import/ export CAD files in STEP format; a large selection of end effectors in the tool library; creation of rectangular box, cylinder for work cell development.

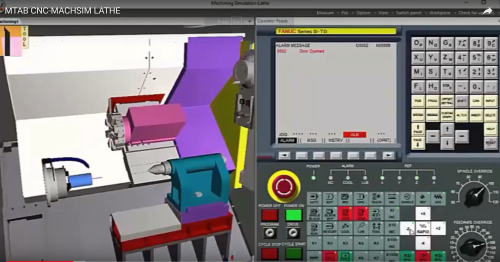

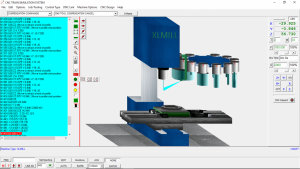

The user can simulation movements such as linear, circular, spline path generation and Joint and Cartesian movements. ARISTOSIM includes features such as ability to import/ export CAD files in STEP format; a large selection of end effectors in the tool library; creation of rectangular box, cylinder for work cell development. CNC-Machsim is a virtual operator training system for CNC Lathe and CNC Milling machine. CNC MACHSIM is an interactive software that allows the user to experience working with 2- axis CNC Lathe and 3-axis CNC mill machine virtually. It includes a full Fanuc control panel and machine control panel with a virtual machine.

CNC-Machsim is a virtual operator training system for CNC Lathe and CNC Milling machine. CNC MACHSIM is an interactive software that allows the user to experience working with 2- axis CNC Lathe and 3-axis CNC mill machine virtually. It includes a full Fanuc control panel and machine control panel with a virtual machine. The user can set different views of the machine and simulate common errors such as collision, alarms, allowing them to learn how to correct and avoid these errors in a live machine. Installing CNC-MACHSIM on a touch screen computer can allow the user experience the industrial controller from a real-world perspective.

The user can set different views of the machine and simulate common errors such as collision, alarms, allowing them to learn how to correct and avoid these errors in a live machine. Installing CNC-MACHSIM on a touch screen computer can allow the user experience the industrial controller from a real-world perspective.Key Features include: ISO tool library for tool selection; Different workholding devices; Work offsets, tool presets; Coolant operation; Tool path simulation; Machine.

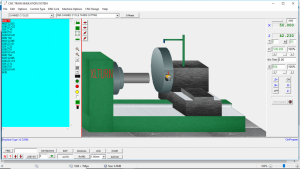

CNCTrain is an easy to use programming and simulation software of 2-axis CNC Lathe and 3- axis CNC Mill, covering setup, MDI programming. CNCTrain has the option of multiple control programming (Fanuc, Siemens, Mitsubishi, Heidenhain). In CNCTrain, the user can enter part program through the Windows editor, On-Screen Control, MDI hardware or generate CAM code using the built-in CAM module.

CNCTrain is an easy to use programming and simulation software of 2-axis CNC Lathe and 3- axis CNC Mill, covering setup, MDI programming. CNCTrain has the option of multiple control programming (Fanuc, Siemens, Mitsubishi, Heidenhain). In CNCTrain, the user can enter part program through the Windows editor, On-Screen Control, MDI hardware or generate CAM code using the built-in CAM module. CNCTrain includes the following modules: CNCWizard, CNCWrite, CNCDesign, CAM, CNCMac, DNC. Key features of the software: 3D Graphics Simulation; Onscreen MDI; Multiple Controls; ISO Programming; Linear & Circular Interpolation; Radius Compensation; CNCTrain features a user-friendly selection window for G&M codes, a wizard to guide beginners through programming syntax, tooling windows for tool selection, offsets, etc. , datum control techniques.

CNCTrain includes the following modules: CNCWizard, CNCWrite, CNCDesign, CAM, CNCMac, DNC. Key features of the software: 3D Graphics Simulation; Onscreen MDI; Multiple Controls; ISO Programming; Linear & Circular Interpolation; Radius Compensation; CNCTrain features a user-friendly selection window for G&M codes, a wizard to guide beginners through programming syntax, tooling windows for tool selection, offsets, etc. , datum control techniques.CNCTrain has a built-in control panel to familiarize trainees with the industrial control panel. Optionally, you can add an external MDI control panel hardware to gain tactile experience of working with industrial CNC panels.